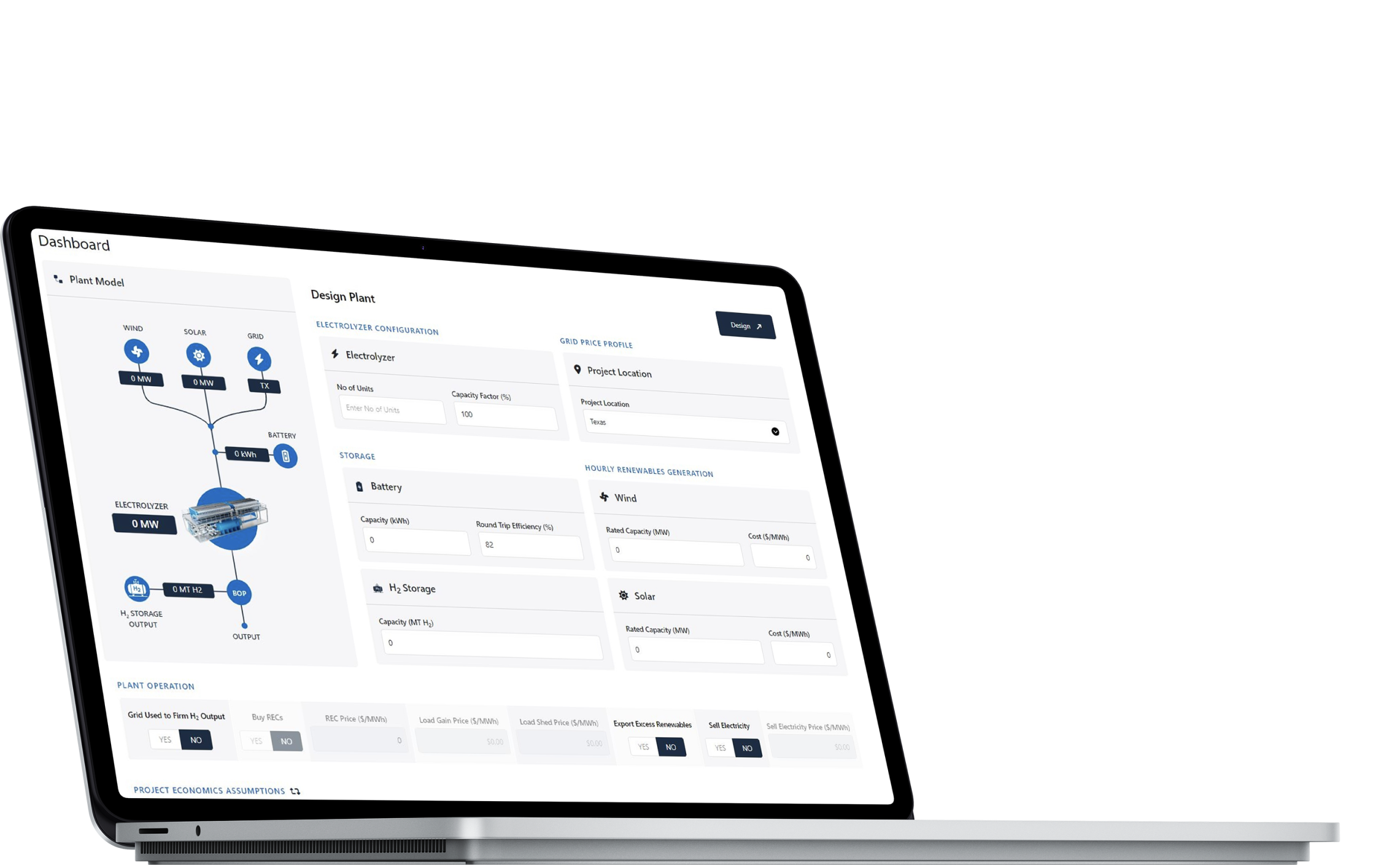

Dynamic Alkaline Water Electrolysis

Verdagy has pioneered Dynamic AWE electrolyzers by developing a patented, single-cell architecture to enable the highest current densities and the widest dynamic range in the industry. Verdagy’s clean hydrogen electrolyzers allow customers to monitor, control and service each cell individually to maximize performance, and continue to upgrade their electrolyzers over the lifetime of the asset.