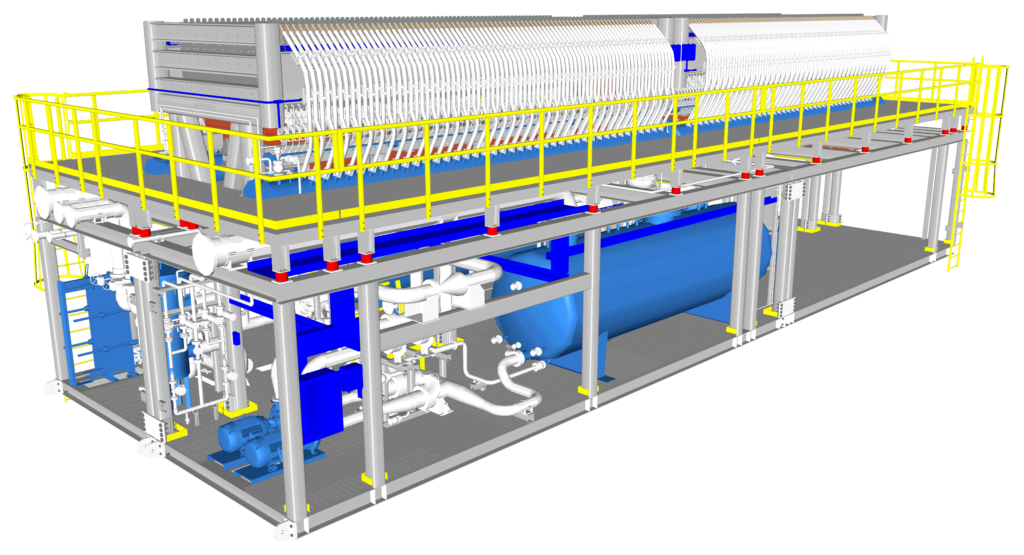

Verdagy’s eDynamic® 20-megawatt Advanced Alkaline Water Electrolysis (AWE) electrolyzer module, serves as a fundamental unit for our green hydrogen systems. Our eDynamic electrolyzer is modular and scalable, enabling customers to develop a plant that meets varying needs, with the ability to combine multiple electrolyzers and operate up to 200-megawatts and beyond.

Our 20-megawatt eDynamic electrolyzer is the basic building block of a green hydrogen power plant that can scale up to gigawatts.

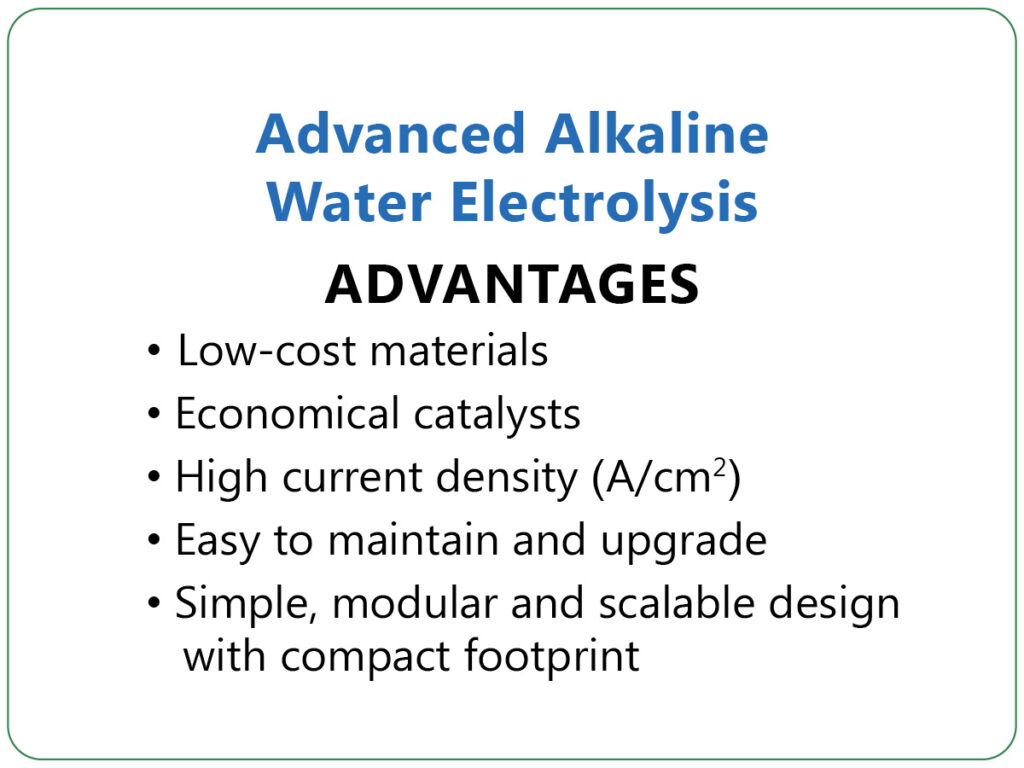

Verdagy Advanced AWE eliminates the barriers that limit traditional AWE by utilizing large, single-element cells operating at high current densities with membrane separation. This system redefines hydrogen production by providing high efficiency, economically attractive, robust operation effective over a broad dynamic range, with an expected product life of more than two decades.

Verdagy is rapidly expanding our commercial activities and we are here to tell you more about how we can help you achieve economically attractive green hydrogen for large-scale industrial applications.